In this issue of Food & Drink Matters, we are pleased to feature Alison Handling as our Handling & Storage Company of the Year.

In the food and drink industry, success is often judged by what reaches the plate or the shelf. Yet behind every finished product lies an unseen infrastructure – the systems, materials and logistics that ensure ingredients move safely, efficiently and without compromise. It is within this vital but often overlooked space that Alison Handling has built its reputation.

In the food and drink industry, success is often judged by what reaches the plate or the shelf. Yet behind every finished product lies an unseen infrastructure – the systems, materials and logistics that ensure ingredients move safely, efficiently and without compromise. It is within this vital but often overlooked space that Alison Handling has built its reputation.

Established in 1988, Alison Handling has grown from a family-run operation into one of the UK’s most respected specialists in plastic storage and handling solutions. From its base in Preston, the company supplies businesses across the food and drink sector with the equipment that underpins day-to-day operations – quietly supporting manufacturers, processors, distributors and hospitality operators as they navigate increasingly complex supply chains. While the company may not always be front of mind, its products are ever-present on factory floors, in cold stores and distribution centres nationwide.

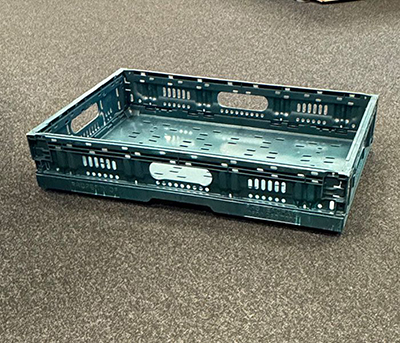

At the heart of Alison Handling’s success is an exceptionally broad and carefully curated product range. As the UK’s largest independent stockist of plastic storage solutions, the company offers everything from Euro stacking containers and bale arm crates to ingredient bins, plastic pallets, dollies and insulated containers. Designed with durability, hygiene and efficiency in mind, many of these products are manufactured using food-grade materials, making them ideally suited to the rigorous standards demanded by food and drink production environments. Smooth surfaces, easy-clean designs and robust load capacities ensure they perform just as reliably on a bakery line as they do in meat processing, beverage distribution or foodservice logistics.

But Alison Handling’s role extends beyond supplying new equipment. The company is also a significant player in the reuse and resale of plastic storage products, buying and selling high-quality used containers to help customers reduce costs while extending product life cycles. This commitment to reuse and recyclability reflects a broader understanding of sustainability – not as a marketing slogan, but as a practical, embedded part of how modern supply chains must operate.

What truly distinguishes Alison Handling, however, is its responsiveness. With extensive warehousing and strong transport links, the company is known for rapid fulfilment, including same-day dispatch on many items and next-day delivery options for time-critical operations. In an industry where delays can mean waste, lost revenue or compromised quality, that reliability is invaluable. Coupled with a knowledgeable and approachable sales team, and by focusing on quality, practicality and long-term partnerships, Alison Handling has become a trusted backbone of the sector – proving that excellence isn’t always loud, but it is always essential.

What truly distinguishes Alison Handling, however, is its responsiveness. With extensive warehousing and strong transport links, the company is known for rapid fulfilment, including same-day dispatch on many items and next-day delivery options for time-critical operations. In an industry where delays can mean waste, lost revenue or compromised quality, that reliability is invaluable. Coupled with a knowledgeable and approachable sales team, and by focusing on quality, practicality and long-term partnerships, Alison Handling has become a trusted backbone of the sector – proving that excellence isn’t always loud, but it is always essential.

In a recent blog – a rare glimpse into how they approach storage solutions at a tactical level – the company outlined how the humble plastic storage box, often taken for granted, can be a powerful engine of organisational efficiency for businesses of all shapes and sizes.

For the food and drink sector in particular, where time, hygiene and traceability are non-negotiable, the principles Alison Handling champions are meaningful. Durable, stackable and easy to access, their storage boxes are designed to maximise valuable space, helping busy kitchens, cold stores, distribution hubs and ingredient preparation areas stay clutter-free and operationally sound. Whether it’s reclaiming vertical shelving space in a bakery or segregating seasonal packaging in a beverage warehouse, these containers turn chaos into clarity – a benefit that reverberates through every stage of production and fulfilment.

For the food and drink sector in particular, where time, hygiene and traceability are non-negotiable, the principles Alison Handling champions are meaningful. Durable, stackable and easy to access, their storage boxes are designed to maximise valuable space, helping busy kitchens, cold stores, distribution hubs and ingredient preparation areas stay clutter-free and operationally sound. Whether it’s reclaiming vertical shelving space in a bakery or segregating seasonal packaging in a beverage warehouse, these containers turn chaos into clarity – a benefit that reverberates through every stage of production and fulfilment.

But efficiency is only half the story. The blog also highlights how the right storage solutions protect inventory from damage – dust, moisture and pests pose real threats in food environments, and well-designed plastic boxes with secure lids offer a sealed, hygienic shelter for dry ingredients, utensils and surplus stock alike. For food and drink operations, this isn’t just convenience; it’s an extension of safety and quality control.

Alison Handling doesn’t just itemise products – they articulate purpose. Clear or labelled boxes make what’s inside instantly visible, reducing search time and smoothing workflows for teams juggling multiple tasks. That kind of operational simplicity enhances efficiency and also contributes to workplace safety, something increasingly valued in food processing, hospitality and catering sectors where cluttered spaces can lead to accidents or compliance issues.

Perhaps most importantly, their solutions are remarkably versatile. Their containers serve diverse sectors – from retail and healthcare to construction and office environments – but the principles remain the same: better organisation supports better business outcomes. In an industry where batch turnovers, seasonal peaks and intricate supply chains are everyday realities, this flexibility translates to a meaningful strategic advantage.

Perhaps most importantly, their solutions are remarkably versatile. Their containers serve diverse sectors – from retail and healthcare to construction and office environments – but the principles remain the same: better organisation supports better business outcomes. In an industry where batch turnovers, seasonal peaks and intricate supply chains are everyday realities, this flexibility translates to a meaningful strategic advantage.

It’s this combination of practical guidance and product excellence that makes Alison Handling more than a supplier; they are operational partners. By helping companies streamline storage, protect stock and enhance safety, they not only make workflows smoother but also contribute quietly to the consistent quality of the wider food and drink landscape.

It is also worth spotlighting how Alison Handling’s expertise resonates with one of the food and drinks sector’s most critical audiences: wholesalers. In its recent feature as a new member of FWD – the Federation of Wholesale Distributors, the company clearly articulated the practical range of solutions it brings to businesses that move and manage stock at scale.

For wholesalers – where operational simplicity, reliability and speed of fulfilment are daily imperatives – Alison Handling doesn’t just supply storage solutions; it tailors them. Its comprehensive catalogue spans lidded and unlidded storage containers, pallet boxes, trays, trucks and pallets, all designed to help distributors move and store products with ease no matter the category on their shelves. These aren’t generic boxes pulled from a catalogue; they are business-ready tools that respond directly to real-world challenges such as space optimisation, hygiene compliance and ease of movement across high-velocity supply environments.

Crucially for food and drink wholesalers, many of these products are available in food-grade materials, ensuring that containers, trays and pallets meet stringent safety and hygiene requirements – a non-negotiable in cold stores, dry goods depots and multi-temperature facilities alike. Alison Handling also serves as the exclusive UK distributor for Saeplast insulated containers, offering temperature-controlled handling options that further broaden its appeal to perishable food sectors.

Crucially for food and drink wholesalers, many of these products are available in food-grade materials, ensuring that containers, trays and pallets meet stringent safety and hygiene requirements – a non-negotiable in cold stores, dry goods depots and multi-temperature facilities alike. Alison Handling also serves as the exclusive UK distributor for Saeplast insulated containers, offering temperature-controlled handling options that further broaden its appeal to perishable food sectors.

But versatility isn’t the only advantage. The company’s approach to service delivery reflects a deep understanding of wholesale workflows. Alison Handling assigns dedicated account managers to its clients, providing hands-on advice, same-day quotations and tailored recommendations that help wholesalers choose the right solutions before inefficiencies take root. Quick turnaround remains a hallmark of their service too: premium next-day delivery and economy options within two to three days mean stock decisions aren’t stalled while supplies are arranged – a logistical lifeline where timing directly impacts shrinkage, throughput and customer satisfaction.

Their commitment to wholesalers is further underscored by the option to make products to order, allowing businesses to specify exactly what they need rather than compromise on off-the-shelf options. It isn’t simply about selling a stack of boxes; it’s about ensuring the right tools are in place for complex storage challenges – whether that’s maximising footprint, segmenting SKUs, or improving the flow between warehouse and delivery vehicles.

This wholesale-centric ethos dovetails with the broader narrative we’ve been tracking: Alison Handling’s products aren’t static assets; they are enablers of operational clarity and commercial confidence. So, for wholesalers navigating competitive pressures, tight margins and evolving regulatory requirements, having a dependable partner in storage and handling isn’t just helpful – it’s strategic.

This wholesale-centric ethos dovetails with the broader narrative we’ve been tracking: Alison Handling’s products aren’t static assets; they are enablers of operational clarity and commercial confidence. So, for wholesalers navigating competitive pressures, tight margins and evolving regulatory requirements, having a dependable partner in storage and handling isn’t just helpful – it’s strategic.

Here at Food & Drink Matters, we recognised Alison Handling as a business that understands the food and drink industry at a fundamental level. From manufacturers and wholesalers to hospitality operators, Alison Handling supports the systems that keep supply chains moving, standards high and waste low. In an environment where margins are tight and expectations relentless, their solutions deliver clarity, confidence and consistency. Quietly dependable yet strategically vital, Alison Handling exemplifies the kind of operational excellence that rarely seeks attention – but unquestionably deserves recognition.

For more information, please see below:

T 01772 687940

enquiries@alisonhandling.com

https://www.alisonhandling.com