Throughout this Food & Drink Matters issue, we have shone a light on sustainability across the sector, highlighting challenges, solutions and innovations.

Established over seventy years ago, award-winning Parkside is a pioneering packaging solutions provider specialising in compostable, recyclable, paper-based and innovative plastic flexible packaging solutions for the food, personal & household care and tobacco sectors. The company is a truly global supplier with manufacturing sites in the UK & Asia and is headquartered in Normanton, West Yorkshire.

Established over seventy years ago, award-winning Parkside is a pioneering packaging solutions provider specialising in compostable, recyclable, paper-based and innovative plastic flexible packaging solutions for the food, personal & household care and tobacco sectors. The company is a truly global supplier with manufacturing sites in the UK & Asia and is headquartered in Normanton, West Yorkshire.

With a focus on the UK Government’s 2050 New Zero Targets and the United Nation’s Sustainable Development Goals accelerating across the country, it is the turn of Parkside to showcase how its ESG policies align with wider green thinking.

United Nations & SME Climate Hub: Concerted push for global sustainability

The 17 Sustainable Development Goals were adopted by all United Member States in 2015 as a pledge for greater sustainability today and for future generations. It is hoped that these goals will be reached by 2030 and include gender equality, ending world hunger, and tackling climate change head-on, whilst encouraging economic, sustainable growth.

Parkside, like many like-minded businesses, has aligned its company’s daily ESG operations and holistic growth to the 17 SD goals through initiatives like the non-profit SME Climate Hub.

The SME Climate Hub works across the globe propelling small and medium sized businesses to take definitive climate action. The Hub is a joint enterprise between the We Mean Business coalition, Exponential Roadmap Initiative, United Nations Race to Zero campaign, with Normative and the Net Zero Team at Oxford University.

“To ensure we meet the SME Climate Hub commitments, we have set several aims. One of the most important is our commitment to reducing our greenhouse gas emissions and overall carbon footprint. We use carbon footprint tracking and reporting software as part of our Climate Hub commitment.”

“To ensure we meet the SME Climate Hub commitments, we have set several aims. One of the most important is our commitment to reducing our greenhouse gas emissions and overall carbon footprint. We use carbon footprint tracking and reporting software as part of our Climate Hub commitment.”

“We have also sourced a zero to landfill waste management company to ensure every aspect of our business is aligned with the circular economy,” explains Julia O’Loughlin, Parkside Group Marketing Manager.

Sustainability accreditations: Responsible sourcing

Parkside is committed to sustainable sourcing and working closely with suppliers to take a holistic view of the end-to-end supply chain. This includes important accreditations from the triple experts: FSC, PEFC, and ISCC.

The Forest Stewardship Council (FSC) is one of the most sought-after global environmental accreditations in the packaging sector. The FSC certifies that all paper and wood supplied to the UK and other countries are sourced from a healthy forest that hasn’t been harmed through felling and that wildlife is protected (the number of trees cut down doesn’t surpass the ability of the forest to reproduce, therefore maintaining a CO2 neutral forest).

The Forest Stewardship Council (FSC) is one of the most sought-after global environmental accreditations in the packaging sector. The FSC certifies that all paper and wood supplied to the UK and other countries are sourced from a healthy forest that hasn’t been harmed through felling and that wildlife is protected (the number of trees cut down doesn’t surpass the ability of the forest to reproduce, therefore maintaining a CO2 neutral forest).

The FSC logo therefore ensures that the products come from the responsible management of the world’s forests and is an instantly recognisable stamp of approval for consumers in the packaging industry.

The Programme for the Endorsement of Forest Certification (PEFC) is an international standard working as an independent monitoring body and currently covers 260 million hectares of forests. It enhances the FSC certification further with sustainable forestry management, with further adaption for smaller-scale land usage.

Lastly, the International Sustainability and Carbon Certification (ISCC) is an independent initiative tasked to certify sustainable, climate-friendly supply chains, which are fully traceable and deforestation-free. The ISCC Certification covers agricultural biomass, biogenic waste, recycled carbon-based materials and non-biological renewable materials.

Sustainable 7 strategy

Sustainable 7 strategy

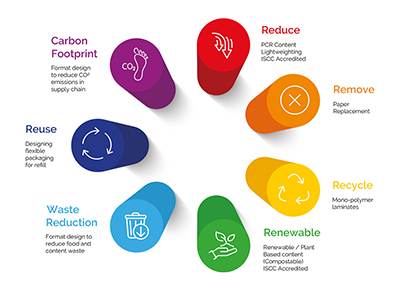

Some packaging companies would gain sustainability accreditations and stop there but Parkside has gone the extra mile through the development of its company strategy. Launched in 2023, the ‘Sustainable 7’ strategy represents the seven pillars that underpin all of Parkside’s packaging projects:

- Reduce

- Remove

- Recycle

- Renewable

- Waste Reduction

- Reuse

- Carbon Footprint.

The 7 pillars mirror the company’s expertise in flexible packaging evolution; namely lightweight and low carbon footprint designs, utilising recycled content solutions as well as recyclable monopolymer film, renewable paper and compostable materials. The packaging substrates are enhanced with high barrier performance for extended product shelf life through the development of laminate structures and the application of innovative barrier coatings. This provides barrier protection against moisture, oxygen and grease, making the packaging suitable for a wide range of food and non-food applications.

“As a flexible packaging expert, our solutions are generally lighter and more efficient to transport than rigid packs, due to their use of more lightweight materials combined with a reduction in the total amount of material being used. This means less empty air is shipped in each consignment and more packs can be shipped in a single container.”

“As a flexible packaging expert, our solutions are generally lighter and more efficient to transport than rigid packs, due to their use of more lightweight materials combined with a reduction in the total amount of material being used. This means less empty air is shipped in each consignment and more packs can be shipped in a single container.”

“We recently expanded our Recoflex™ range of, recyclable paper-based packaging. The original application for this material was an award-winning freezer-proof paper pouch for seafood – the first fully functional recyclable paper pack of its kind.”

“We’re working on long-term projects with a number of household name brands to develop materials suitable for large-scale product launches,” elaborated Julia.

Spotlight on the award-winning Recoflex™ range

The freezer-proof seafood paper pouch was designed for supermarket giant: Iceland as part of their North Coast range of frozen seafood. The innovative design won the prestigious Stationers’ Company Innovation Excellence Award in the Product Design category. The winning design was made with Recoflex paper materials, treated with a water-based coating that acts as a moisture and grease barrier, whilst also cleverly preventing ice crystals from forming on the exterior pack. This is a game-changer in the paper-based freezer-proof flexible packaging sector, as Julia adds, “We recently launched a metallised paper into the Recoflex range, which uses an advanced aluminium deposition technique to create a high barrier metallised flexible material that can still be certified as recyclable. This complements the rest of the range, which includes a flow wrap, a high-barrier PET laminated paper, and a translucent option.

In defence of plastic

“Plastic is often seen as the villain of the story, when quite often it is the most sustainable option when you take a holistic view of the whole supply chain. For one, it offers optimum barrier protection and helps to reduce food waste, which has a much greater global carbon footprint than packaging waste does. Plastic is also a lightweight material, meaning it can help reduce transport emissions in some applications.”

There are other timely challenges for the whole packaging sector as Julia illuminates, “The cost of materials, particularly rising costs stemming from the lack of availability of recyclate for use in post-consumer recycled content materials, is an issue for everyone. The growing demand for recycled and recyclable materials highlights the continued lack of recycling infrastructure in the UK, which means some categories of plastic that could in theory be recycled still end up in landfill or incinerated. This is particularly pertinent for flexible plastics, which are commonplace throughout the industry but without compatible recycling infrastructure to match. As a result, many brands and retailers find themselves unable to fulfil their ESG goals and pledges.”

Looking forward with next-level innovations

Parkside embraces new technology, as part of the emerging Industry 5.0 sector to promote next-level packaging solutions, such as the laser scribing and scoring system ParkScribe™.

“We can score peel-and-reclose flaps into lidding film to create an integral opening mechanism. When weld-sealed to a rigid tray of the same material – for example, a PET film can be welded to a PET tray – this enables the creation of trays and punnets that are then deemed suitable for recycling as one unit under current OPRL guidelines.”

Parkside Flexibles:

T +44 (0)1924 898074

info@parksideflex.com

www.parksideflex.com