Celsius Instruments has been chosen as our respected Measurement Instrumentation Provider of the Month, we are excited to inform our readers here at Food and Drink Matters.

The company is initially based in Milton Keynes in the UK, but as a strategically developed division of the renowned production, test and measuring equipment and packaging manufacturer Molins PLC, is operational internationally. Although it was only established in 2015, the group has enjoyed world-wide success courtesy of its involvement with the reputable solutions provider and has since built itself a solid customer network serviced effectively by its well-placed offices in areas such as India, Singapore, China and the USA.

The company is initially based in Milton Keynes in the UK, but as a strategically developed division of the renowned production, test and measuring equipment and packaging manufacturer Molins PLC, is operational internationally. Although it was only established in 2015, the group has enjoyed world-wide success courtesy of its involvement with the reputable solutions provider and has since built itself a solid customer network serviced effectively by its well-placed offices in areas such as India, Singapore, China and the USA.

Employing over 800 people, Molins is split into two core departments: packaging machinery and instrumentation & tobacco machinery. Predominantly serving the fast-moving consumer goods sectors (with food and tobacco being the main product areas of focus), the business strives to supply machinery of the highest standard (along with the associated support services and systems). Celsius Instruments operates as part of the Instrumentation division.

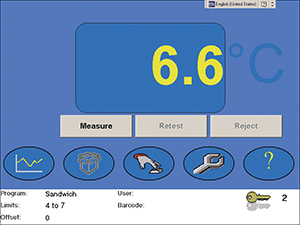

“Celsius Instruments offers a fast and non-destructive method of measuring chilled products in a simple, repeatable manner,” commented Andy Slater, Sales Manager at Celsius Instruments. “With the Celsius range of devices, you can be assured of accurate and consistent measurements using an easy to use and read measurement device. Our technology removes the need to measure the temperature of chilled products with a probe and the inherent uncertainty of “was the product measured correctly?” while eliminating the waste associated with the destructive test.”

Designed to measure the average temperature of frozen and chilled food-stuff (and other such items), the non-invasive thermometry systems incorporate a unique technology which resolutely measures the tiny amounts of microwave radiation emitted by the product in the chamber. This is then converted into a temperature, which is attained by taking into account the item in its entirety for the purposes of complete accuracy and repeatability.

Andy explained further, “When food is cooled quickly, the temperature reduces at different rates, depending on the size and density and will usually result in cold-spots and hot spots. Because thermocouple probes only measure a single point, it will probably be impossible to know exactly what you are measuring. Celsius removes all the uncertainty by displaying a temperature that accounts for all the hot and cold spots, giving an ‘equalised’ temperature. In addition, no damage is inflicted upon the product, meaning it can be used at various times during the cooling process to optimise the cooling time and increase throughput.”

The products, which are manufactured in the UK, are popular with both large chilled and frozen food manufacturers and smaller businesses, who appreciate the money-saving and efficiency-increasing benefits associated with utilising Celsius’ impressive solutions. Other particular benefits over the traditional (and fundamentally more damaging) testing methods include added calibration options (which in turn ensure greater customer confidence), the eliminated possibility of mistakes and finally, the omitted need for trained operators, who normally must be present to take the necessary product temperatures.

The products, which are manufactured in the UK, are popular with both large chilled and frozen food manufacturers and smaller businesses, who appreciate the money-saving and efficiency-increasing benefits associated with utilising Celsius’ impressive solutions. Other particular benefits over the traditional (and fundamentally more damaging) testing methods include added calibration options (which in turn ensure greater customer confidence), the eliminated possibility of mistakes and finally, the omitted need for trained operators, who normally must be present to take the necessary product temperatures.

T 09108 396111

andy.slater@celsius-instruments.com

www.celsius-instruments.com