Automatic Inline Checkweighers have been part of our production lines for decades and it is estimated that in the UK alone there are 4.9 million products checked by inline checkweighers every minute.  Despite this large number there is still widespread misunderstanding on how you should measure the accuracy of a checkweigher and even greater confusion on how to comply with the regulations.

Despite this large number there is still widespread misunderstanding on how you should measure the accuracy of a checkweigher and even greater confusion on how to comply with the regulations.

Unlike most of Europe the UK has no requirement for a checkweigher to be trade approved, meaning type approved and verified for trade use. That means that a checkweigher placed on the UK market is not required to have any guaranteed accuracy.

It is for this reason that it is essential that the accuracy is checked to ensure it complies with all the regulations and countless codes of practice. There are many publications available today that offer information and guidance on inline checkweighers. It is unfortunate however that the large majority of these are overcomplicated and use unknown words or abbreviations along with complex calculations. In the rare texts where it is understandable it is often far too open to interpretation, which again adds to the misunderstanding.

In this article we will explain in simple terms how to precisely measure any checkweigher accuracy, document and prove that accuracy. The method used is that required by the Package Goods Regulation and the same method used by the authorities responsible for governing compliance with the regulation. In short, this is the only recognised method for determining accuracy of a checkweigher.

On any weighing instrument, there are two areas for error that will determine the accuracy of the equipment. The first is the repeatability and the second is exactness to a known mass, such as calibrated weight. These two factors are the only similarity between dynamic weighing (inline checkweigher) and static weighing (scales).

In some documents, you will read of additional factors such as, environmental conditions, temperature, uncertainty of measurement, variability of product or tare, air buoyancy and so on. In this test you can forget these as we are measuring with the product and in the environment it will be used.

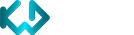

The most common misunderstanding is that an inline checkweigher should be calibrated the same as a static scale, meaning you stop the transport system, place weights on the weighing conveyor and if this is OK then the checkweigher is accurate. This is not true as you have to consider the additional errors introduced when you start the conveyor and the checkweigher is working with additional vibration and in motion. This is a big factor and fundamentally only a checkweigher that has a weigh cell that is designed to work in this way will in many cases meet the required accuracy.

The most common misunderstanding is that an inline checkweigher should be calibrated the same as a static scale, meaning you stop the transport system, place weights on the weighing conveyor and if this is OK then the checkweigher is accurate. This is not true as you have to consider the additional errors introduced when you start the conveyor and the checkweigher is working with additional vibration and in motion. This is a big factor and fundamentally only a checkweigher that has a weigh cell that is designed to work in this way will in many cases meet the required accuracy.

While static calibration, as the only form of calibration is pointless, for the service engineer a starting reference should be used to determine the dynamic weight. For example, the checkweigher can weigh a product at 500g statically but when in motion the display shows 502g, the checkweigher would need to correct the dynamic by -2g. Ideally, a checkweigher’s auto dynamic calibration will adjust for this by taking a static reference first and then measuring the difference and adjusting.

The other misunderstanding is passing a known weight across the checkweigher, such as a calibration weight. This calibration weight even if it is the same weight as your product will have a different dynamic effect than your product as it is transferred across the weighing conveyor. This will give different results mainly due to its difference in length and shape.

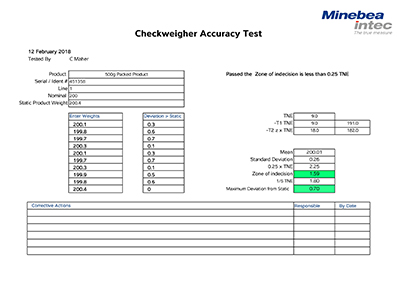

One of the first checks is to determine the Zone of Indecision (Zoi). This is not as sinister as it sounds but simply 6 times the standard deviation of a number of readings with the same product. The Zone of Indecision is globally accepted as a calculation that factors for the uncertainties attributed to dynamic weighing.

Doing this test will determine the repeatability of the checkweigher with the product. You should always start with the repeatability, as the other test to a known mass cannot be determined without a stable repeatable reading first.

In order to do this you should do the following – pass the same product 10 or 20 times over the checkweigher, ensure that you pass the product in the direction it would be during production.

In order to do this you should do the following – pass the same product 10 or 20 times over the checkweigher, ensure that you pass the product in the direction it would be during production.

- Record these individual values, on some Checkweighers there is a function to automatically record and even display the required standard deviation. If not excel has a built in formula to do this called STDEV.

- Once you have the standard deviation multiply this by 6 and that is your Zone of Indecision.

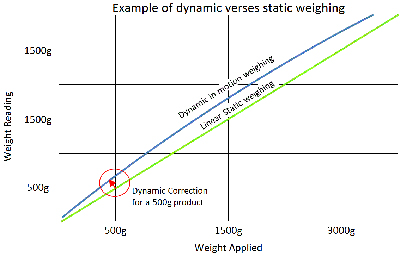

- From the table calculate your TNE (-T1), for example if your product is 200g then your TNE (-T1) is 5% or 9g.

- You should now calculate a quarter (0.25) of this 9g, 0.25 of 9g = 2.25g. This value is your repeatability limit.

- If the Zone of indecision is greater than the 2.25g (quarter of TNE) then the checkweigher cannot be used with the set points, (reject limits) shown in the table.

This test should be done and recorded for all product types and weights used on that checkweigher. It is good practice to repeat this test over a period and build up a trend analysis, this will indicate how variable it is over time, and will then determine how frequently you will need to perform this test in the future. These records along with the trend analysis form the proof of the risk assessment detailed in the retailer’s code of practice.

The second test is for the exactness to a known mass, which is also done using the product along with a static scale, calibrated to national standards. The static scale should be capable of reading to the same resolution as the checkweigher or better.

These checks should be done before, during and after a batch. By recording the weights a trend analysis can be made which can form the data for a risk assessment as required in some of the codes of practice.

- Using a calibrated weight traceable to national standards and as close to the product weight as possible check that the static scale is weighing correctly.

- Note the weight of a pack as it passes over the checkweigher and then weigh this on the static scale, if the difference is within 1/5 (1 fifth) TNE then the checkweigher is suitable to be used. Some checkweighers have a built in weight check function and will reject a product and hold the weight of that product on the screen.

- In order to make a check on the repeatability of the checkweigher at that time it is good practice to repeat this test at least once.

For example, we have a product with a nominal of 200g, when we weigh this on the checkweigher it reads 200.4g. Weighing this same product on a static scale, it shows 199.7g a difference is 0.7g. We know our TNE for a 200g product is 9g and one fifth of this is 1.8g. The 0.7g is less than 1.8g limit therefore this checkweigher is accurate enough to comply.

Under the Package Goods Regulation and Codes of Practice, it states, “Any measuring equipment used for quality checks must be suitable for the purpose to which it is used.” While this statement remains open to interpretation, the regulation references, a minimum resolution of weighing equipment that must be used and trade verified for offline static weight sampling of product.

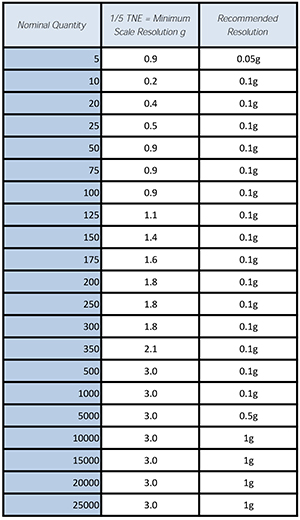

Adjacent is a table showing the minimum resolution of scale, which is determined by the declared nominal weight of product. It is good working practice to use this same resolution of checkweigher and static scales used to check the checkweigher.

If you would like more information on the regulations, codes of practice or a copy of the checkweigher accuracy document, please email us at: explanation@minbea-intec.com